Data monetization is transforming business models in the manufacturing industry, enabling companies to harness their data as a strategic asset. With Industry 4.0 introducing automation, IoT, and advanced analytics, and Industry 5.0 emphasizing human-machine collaboration and sustainability, data is no longer just a byproduct of operations—it is a powerful asset. Monetizing this data has become a strategic imperative, enabling manufacturers to drive revenue, optimize operations, and gain a competitive advantage.

In this article, we explore how manufacturers can effectively monetize their data, the technologies enabling this transformation, and actionable strategies to thrive in the era of smart manufacturing. Predictive maintenance, real-time monitoring, and digital transformation are critical enablers of this shift.

Unlocking economic benefits through data monetization strategies

Traditionally, manufacturers focused on physical outputs—raw materials in, products out. But today, digital outputs (manufacturing data) are just as valuable. Machines, IoT sensors, supply chains, and enterprise systems generate vast amounts of raw data every second. This data holds critical insights into performance, efficiency, customer behavior, and market demand.

Data monetization refers to turning these insights into economic value directly (selling data or data-driven services) or indirectly (improving processes, reducing costs, enhancing products).

Some key benefits of data monetization in the manufacturing industry include:

- Operational efficiency: Predictive maintenance, quality control, and energy optimization.

- Enhanced customer experience: Personalized offerings, expedited service, and superior quality.

- Product innovation: Product usage data helps to refine or develop new products.

- Competitive advantage: Data-driven decisions are faster and more accurate.

Industry 4.0: building business performance with data monetization

Industry 4.0 lays the groundwork for data monetization by digitizing the manufacturing environment, enabling the seamless integration of data and promoting data sharing across various systems. This transformation is powered by data analytics and other technologies that help manufacturers harness their full potential. The key enablers include:

1. Industrial internet of things (IIoT)

Smart sensors and connected devices capture real-time data from equipment, production lines, and products in the field. This provides rich datasets on machine health, throughput, environmental conditions, and other relevant metrics.

Monetization example: A machine builder can sell predictive maintenance services based on IIoT data collected from customer sites.

2. Cloud computing and edge computing

Cloud platforms enable scalable storage and processing of big data, while edge computing allows data to be analyzed closer to its source, reducing latency and bandwidth requirements.

Monetization example: Manufacturers can offer real-time analytics platforms to customers or partners, charging subscription fees for this service.

3. Artificial intelligence and machine learning

AI models can uncover patterns, predict failures, and optimize production in ways humans cannot. Machine learning algorithms improve over time, creating a sustainable data advantage.

Monetization example: Utilizing AI to optimize factory operations can also enhance profitability.

4. Digital twins

A digital twin is a virtual replica of a physical process, product, or system. It uses real-time data to simulate performance and predict outcomes.

Monetization example: Offer digital twin simulations to OEMs or clients for design testing or remote monitoring.

Industry 5.0: elevating data monetization with human-centric innovation

Industry 5.0 builds upon Industry 4.0 by integrating human creativity with smart technologies, emphasizing personalization, sustainability, and resilience. This evolution in the manufacturing industry highlights the importance of data monetization strategies, data integration, and data analytics to create new revenue streams and enhance business performance.

1. Human-machine collaboration

Cobots (collaborative robots) and AI-assisted systems enhance human capabilities rather than replace them. This generates manufacturing data on user interactions, task efficiency, and ergonomics.

Monetization strategy: Utilize human-machine interaction data to optimize workflows and allocate human employees to higher-value tasks. Data analytics can also uncover hidden patterns to further improve productivity.

2. Hyper-personalization

Manufacturers can leverage customer and product data to offer mass customization on a large scale. This requires deep data sharing on customer preferences, usage behavior, and feedback loops.

Monetization strategy: Offer customized products at a premium or provide customer insights to retail partners, generating new revenue streams.

Pathways to data monetization in manufacturing

Monetizing manufacturing data can be approached in various ways.

Operational monetization

This is the most immediate and impactful approach. Use data to reduce costs, increase productivity, and eliminate downtime.

- Predictive maintenance: Avoid unplanned outages by analyzing equipment data.

- Process optimization: Fine-tune production lines based on performance metrics.

- Supply chain visibility: Utilize real-time data for enhanced forecasting and inventory control.

Product-as-a-platform (PaaP)

Embed sensors and connectivity into products and offer insights as part of the product package.

Example: A machine that reports real-time usage data to the customer and the manufacturer, enabling usage-based pricing or remote diagnostics.

How manufacturers leverage data analytics for business performance

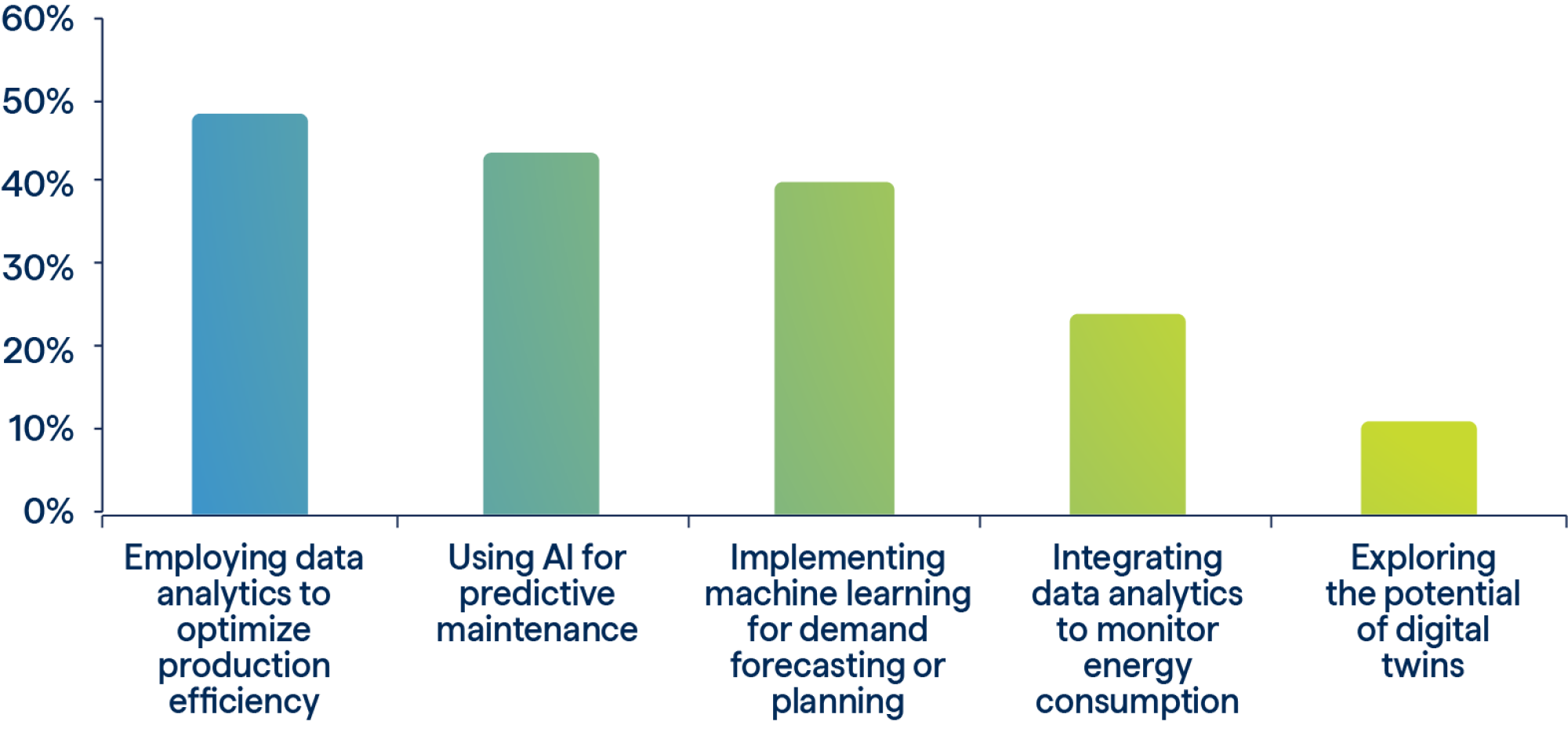

In Alithya’s 2025 Manufacturing Trends Report, based on a survey of manufacturing professionals, almost 50% of respondents indicated they plan to employ data analytics to optimize production efficiency, while approximately 23% said they plan to integrate data analytics to monitor energy consumption.

Respondents were asked to check all that apply

Enhanced intelligence from data analysis has helped accelerate growth in the US manufacturing sector. For instance, after two decades in which manufacturing growth stagnated at 1.4%, recent developments mean that shareholders are now seeing returns of about 400 basis points higher than in the prior 15 years.

Predictive maintenance, real-time monitoring, quality assurance, increased production efficiency, and supply chain optimization are among the biggest benefits manufacturers can achieve by making improvements in data analysis.

Overcoming challenges in data monetization for the manufacturing industry

While the potential is vast, data monetization in manufacturing isn't without hurdles.

1. Data ownership and privacy

Who owns the data—the manufacturer, the customer, or the machine builder? Clear contracts and policies must define rights and usage.

2. Security and compliance

Sensitive production and customer data must be protected. Cybersecurity is a major concern, especially in highly regulated industries.

3. Data quality and integration

Fragmented data silos and inconsistent formats can limit monetization opportunities. Data governance and integration frameworks are essential.

4. Change management

Cultural resistance, lack of digital skills, and outdated legacy systems can slow adoption. Success requires executive buy-in and upskilling the workforce.

A step-by-step guide to data monetization in the manufacturing industry

If you're ready to begin monetizing your manufacturing data, here’s a practical checklist:

Step 1: Audit your data assets

- What data is collected today?

- Where is it stored?

- Who has access?

Step 2: Identify monetization opportunities

- Operational improvements

- Data-as-a-service offerings

- Product enhancements

Step 3: Build the right tech stack

- Invest in IoT, cloud, AI, and analytics tools.

- Ensure interoperability and scalability.

Step 4: Create governance and monetization models

- Define data ownership, sharing rights, and revenue-sharing models.

- Consider legal and ethical implications.

Step 5: pilot and scale

- Start small—choose one process or product line at a time.

- Measure impact, learn, and expand.

Partner with Alithya to accelerate data monetization in the manufacturing industry

In the era of Industry 4.0 and 5.0, data is not just a resource but a revenue generator. Manufacturers can unlock new value streams by strategically leveraging the data generated across smart factories, transforming business models, and staying competitive in a rapidly evolving market.

Those who master data monetization will optimize their operations and lead the next industrial revolution—one in which innovation, intelligence, and insight drive growth.

Alithya’s experience working with hundreds of manufacturing clients gives us the unique ability to help you unlock the power of data. Alithya can help you combine and validate datasets, ensure proper handling of sensitive data, and leverage advanced analytics to reveal valuable insights. Let’s connect and explore a tailored strategy for your business.

Key sources and references

- Manufacturing Leadership Council - The Reach for Data Monetization

- CLOUDSUFI - Data Monetization in Manufacturing: Strategies for Success

- Number Analytics - 6 Data Monetization Insights Revolutionizing Modern Manufacturing

- Gross Mendelsohn - Industry 5.0 Brings a Shift to Human-Centered Innovation in Manufacturing

- Rutgers-New Brunswick School of Engineering - Industry 4.0 vs 5.0: What's the Difference?

- Stibo Systems – A Data Monetization Strategy