The planned orders form in Microsoft Dynamics 365 can be confusing when dealing with its multitude of date fields. In this blog, we help you make sense of the Requested date and the Requirement date fields on the Planned orders and the Pegging form.

Better Understand the Requested Date and Requirement Date Fields on the Planned Orders and Pegging Form in Dynamics 365 FO

Dates on Planned Order forms:

Requirement Date: This is the date when the customer needs the order to be shipped. In the case of Production, this is the date by which the item should be made. In the case of Forecast it will be the date of the forecast. If the original date that the customer requested cannot be met, then this date becomes the actual date that the request can be met.

Requested Date: If the requirement date cannot be met, then the system will show the original date as the requested date and the requirement date will show the date when the requirement can be met.

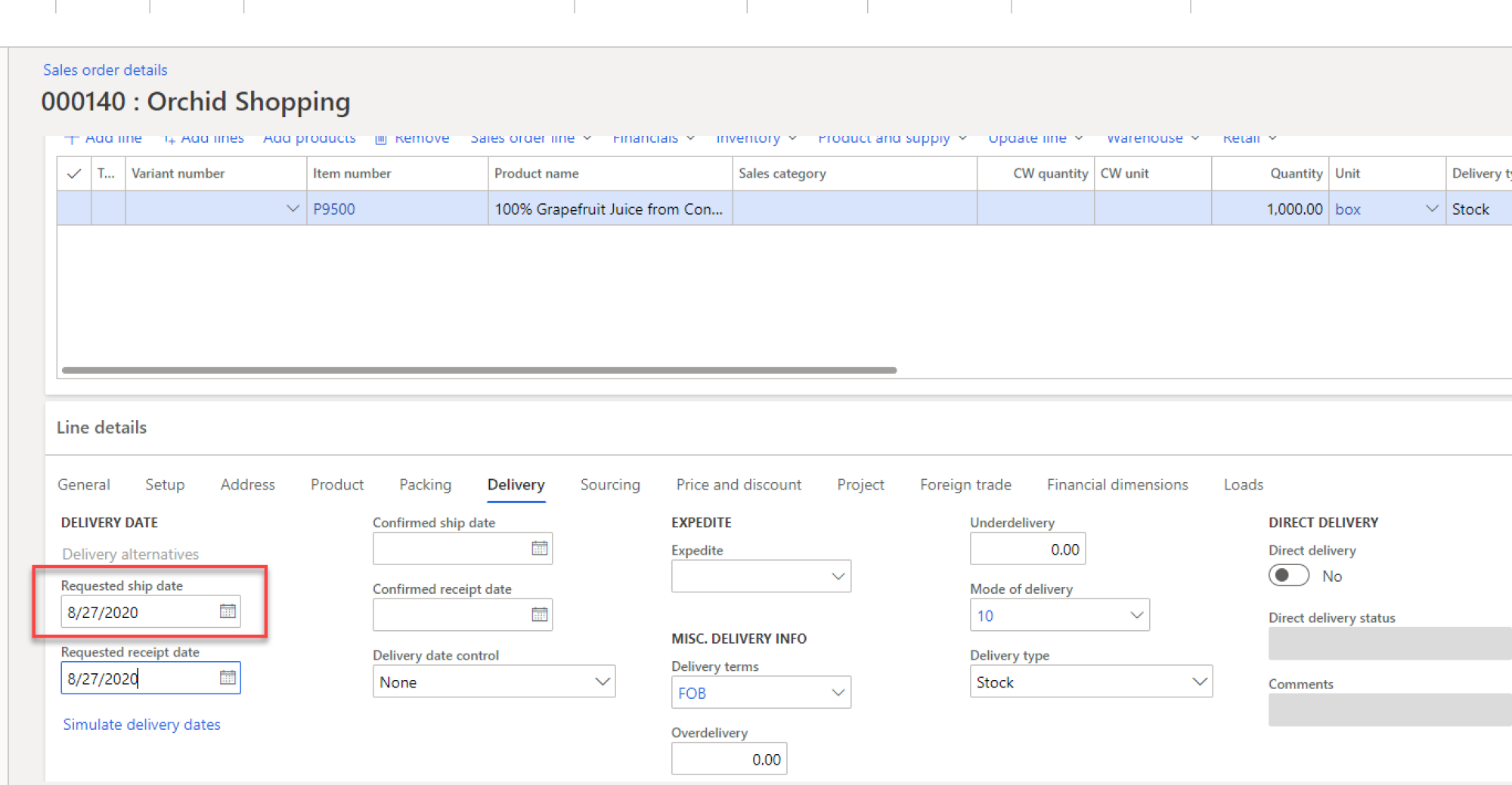

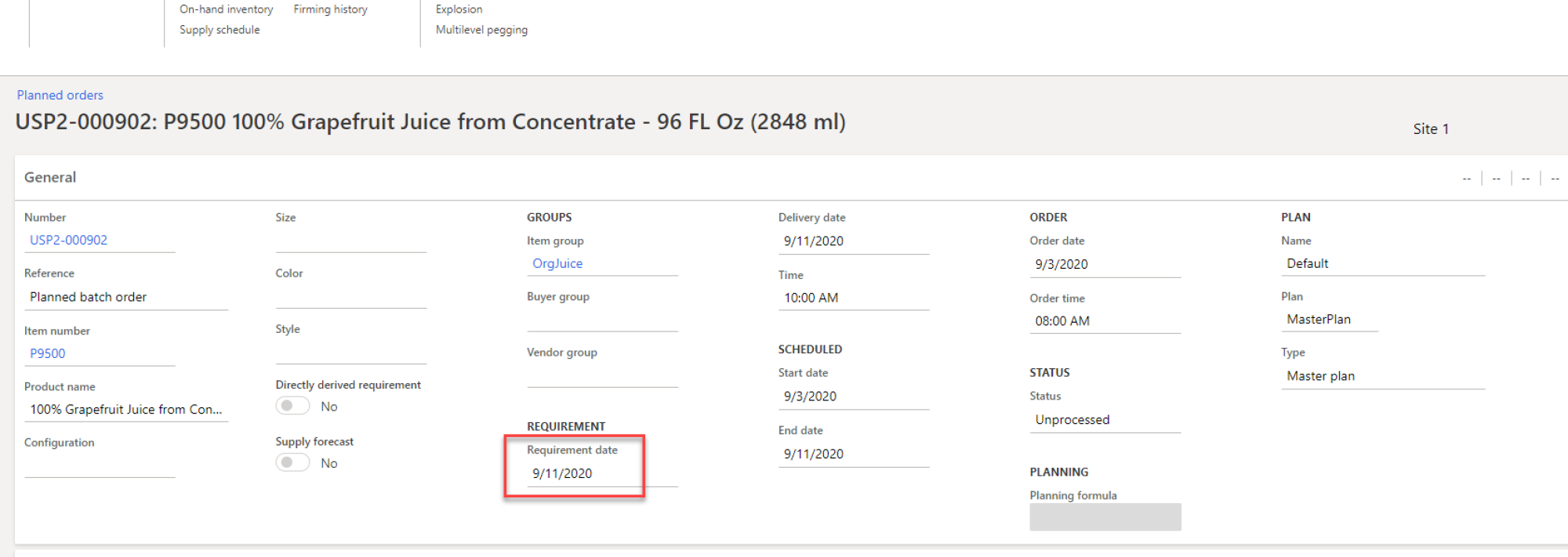

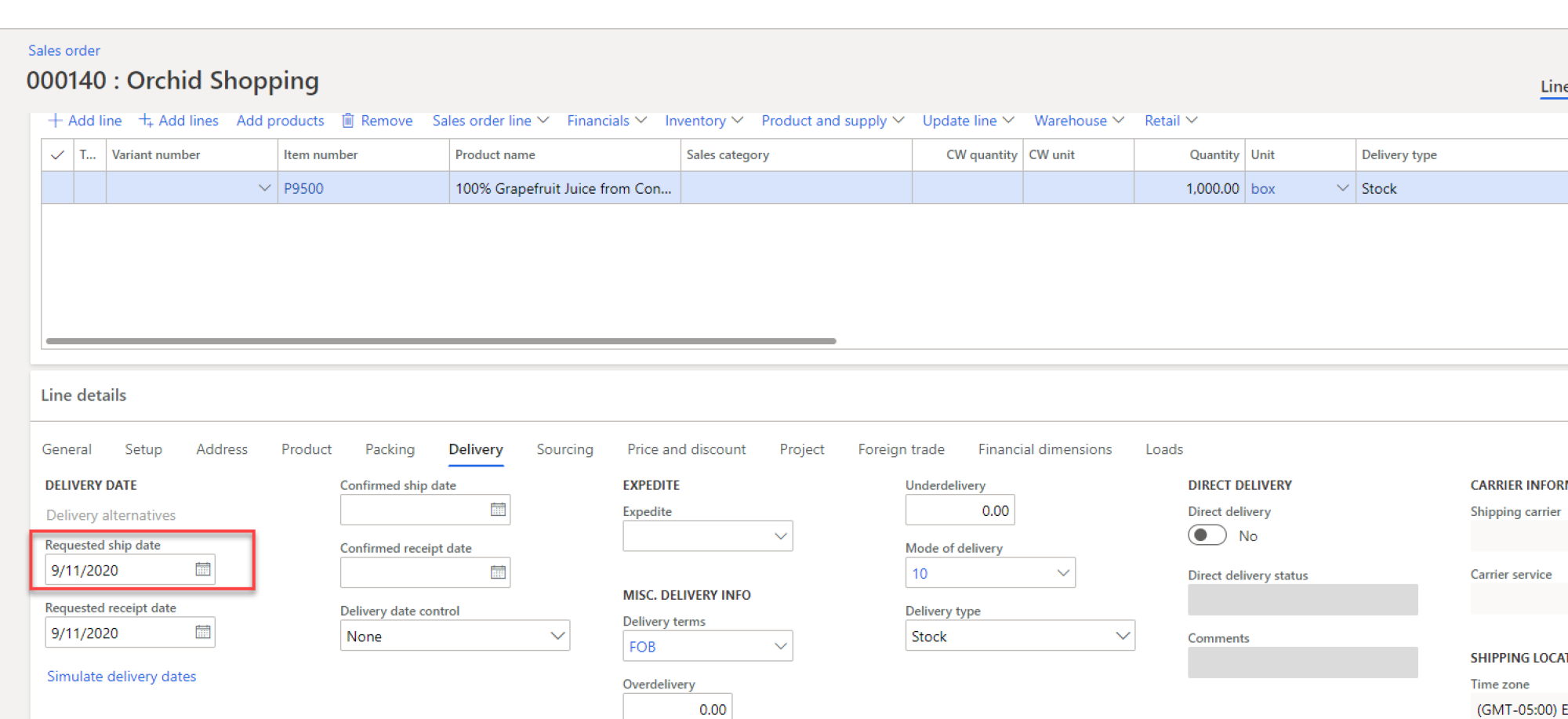

Case I: We will use Sales orders to drive the planned orders.

In the example below the sales order has a ‘Requested Ship Date’ of 09/11/2020

- If we run the Master planning, we should see the requirement date as 9/11/2020 on the planned order

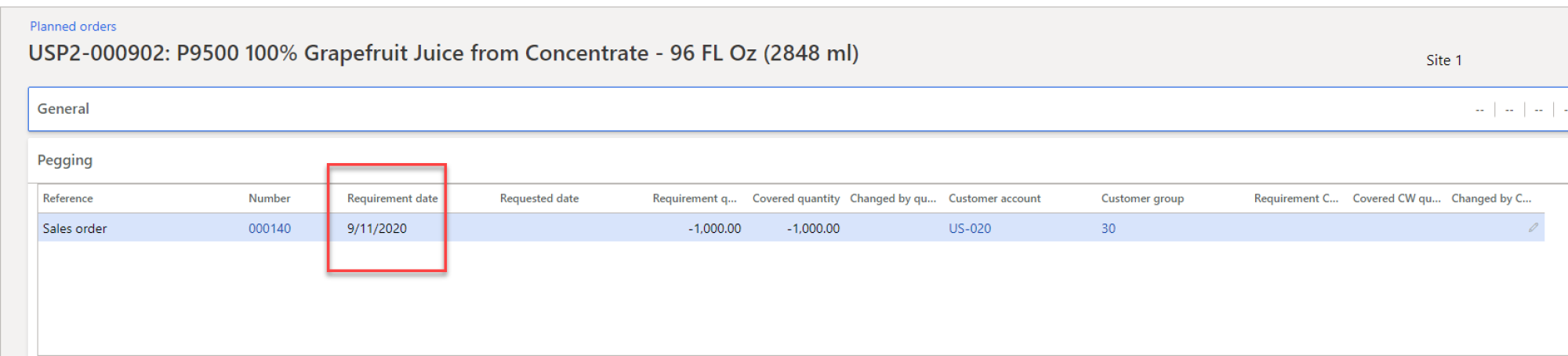

- On the pegging tab, the ‘Requirement date’ is as 9/11/2020

- In this case there is no ‘Requested date’ on the pegging tab.

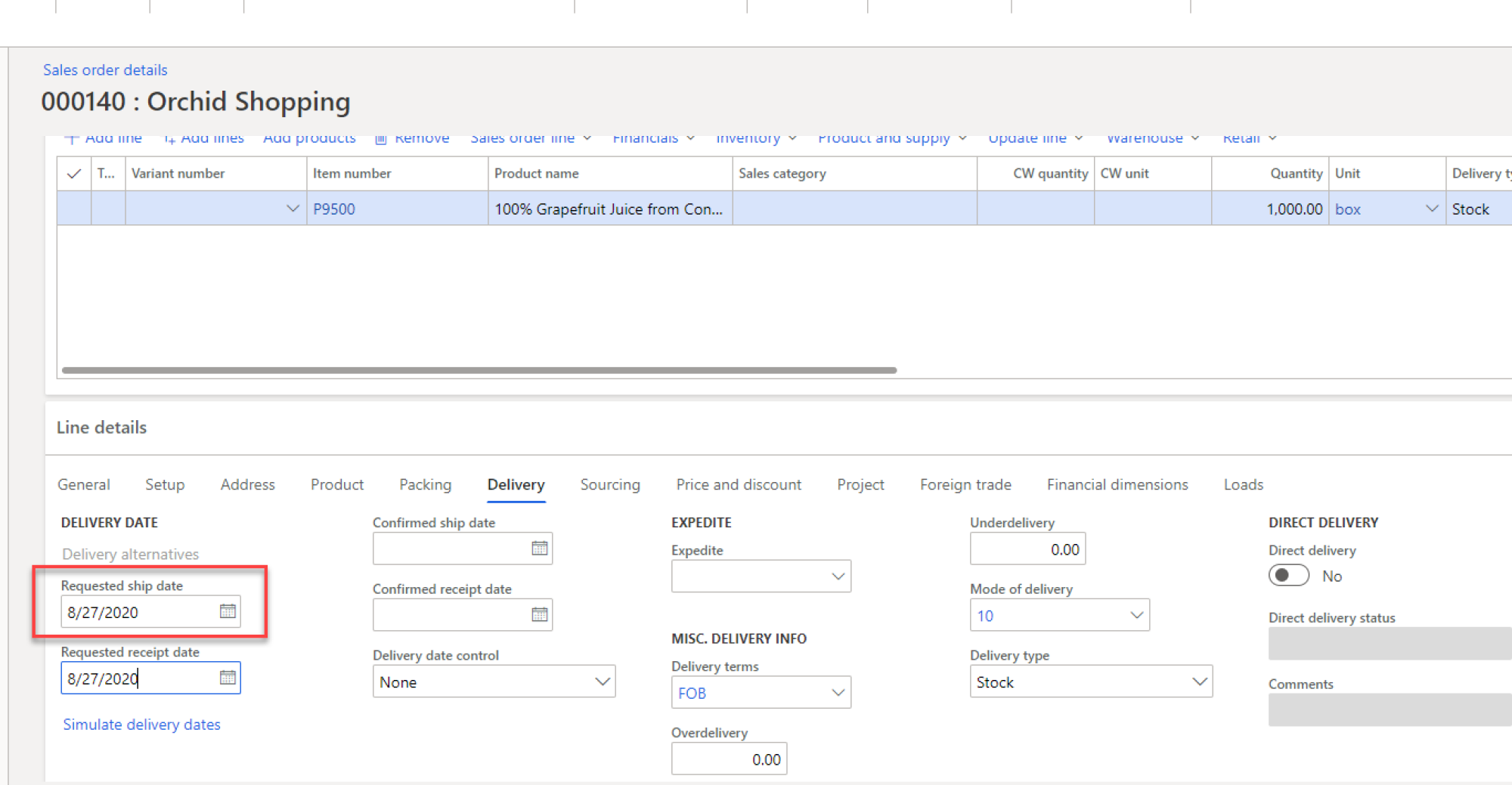

Case II: Lets change the Requested ship date on the Sales order to 8/27/2020, so that the order cannot be delivered to the customer in time.

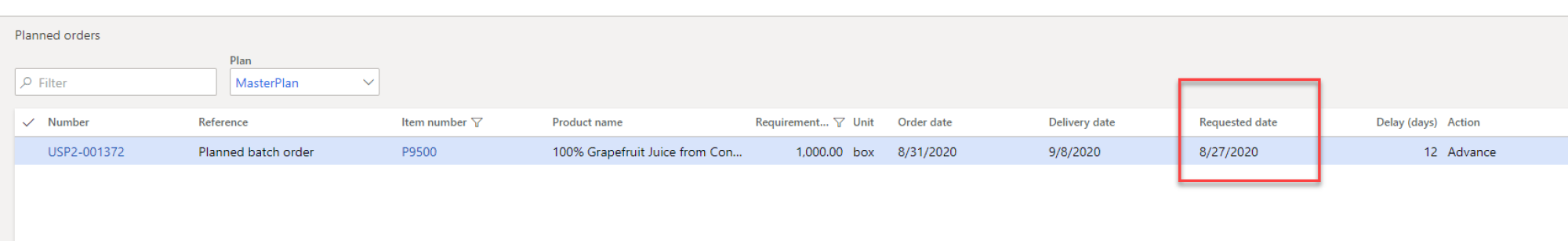

- In this example the system cannot meet the requested date and so we will get futures and action messages.

We see the requested date in this case is 8/27/2020, which was our requested ship date.

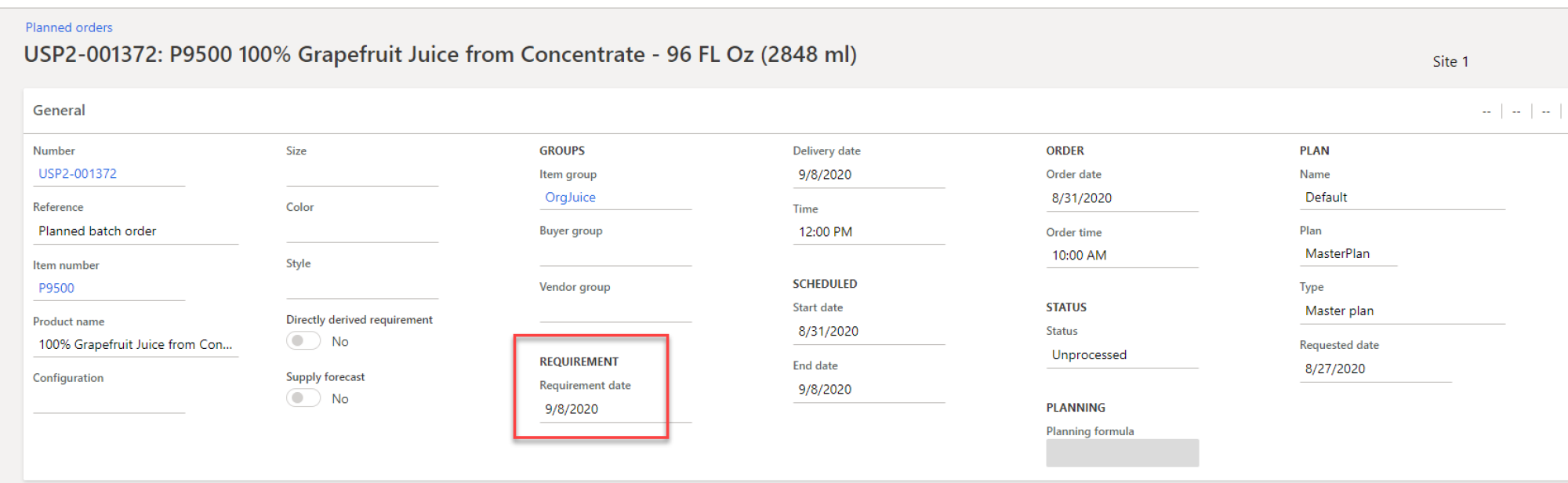

- But when we look at the requirement date, it shows a date of 9/8/2020. That is the date we can make this item and ship it to the customer.

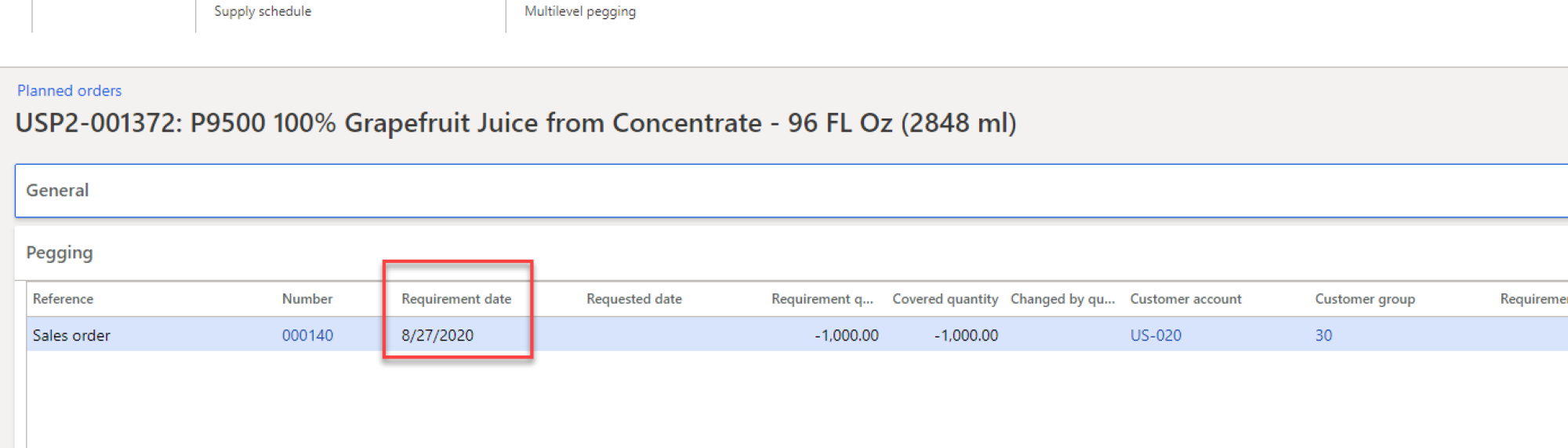

- The requirement date on the Pegging remains at 8/27/2020.

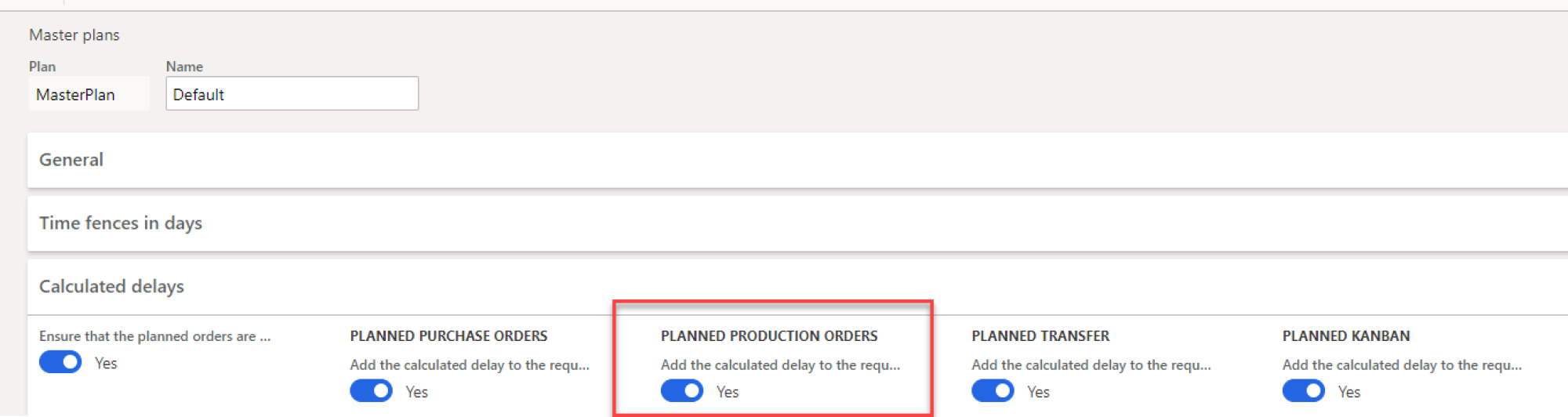

- In this example the ‘Add calculated delays to requirement’ date was checked

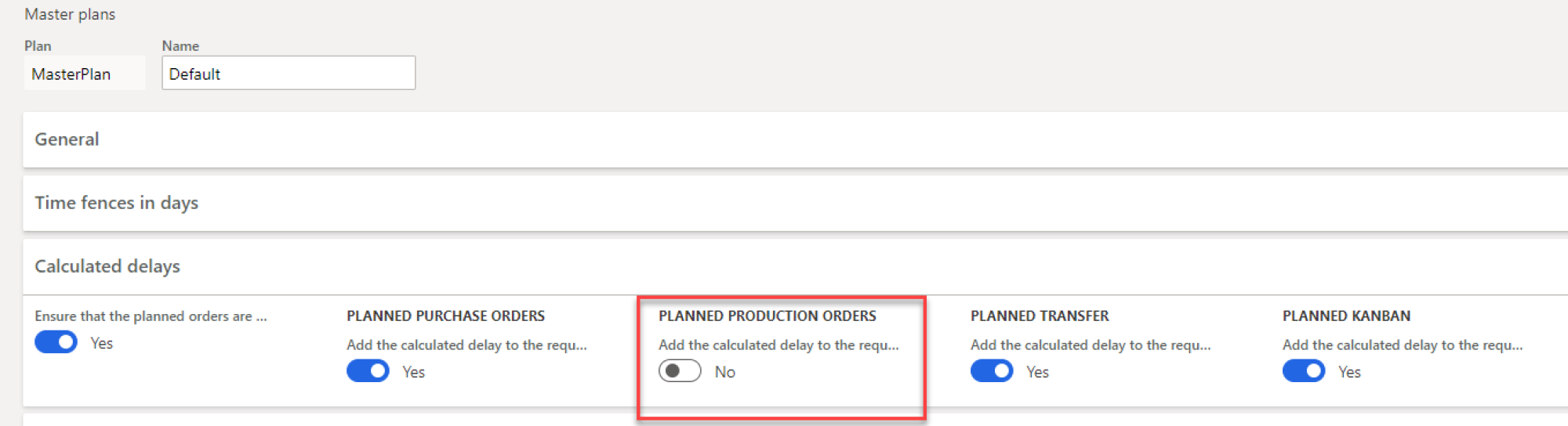

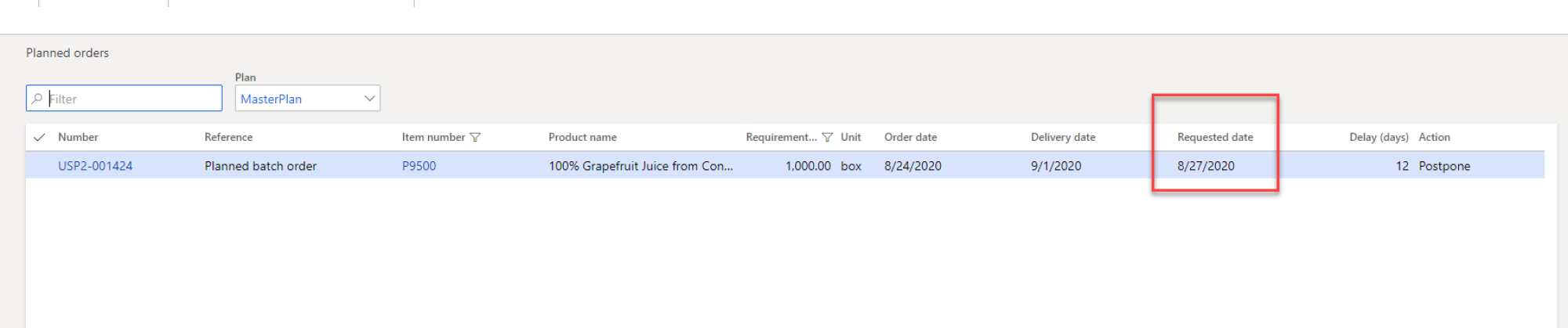

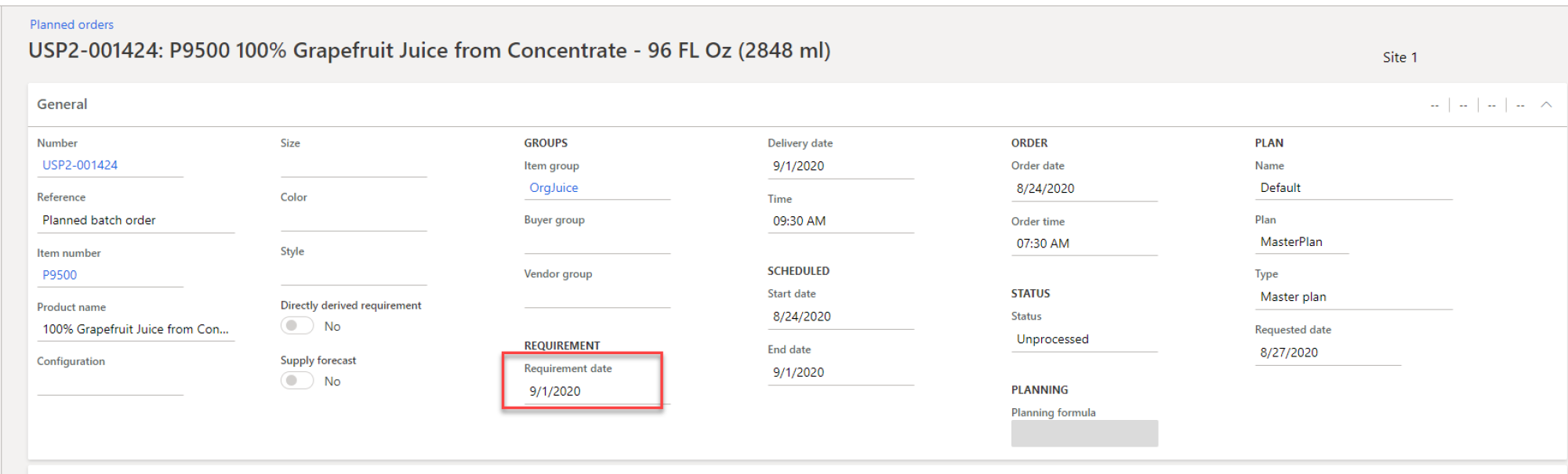

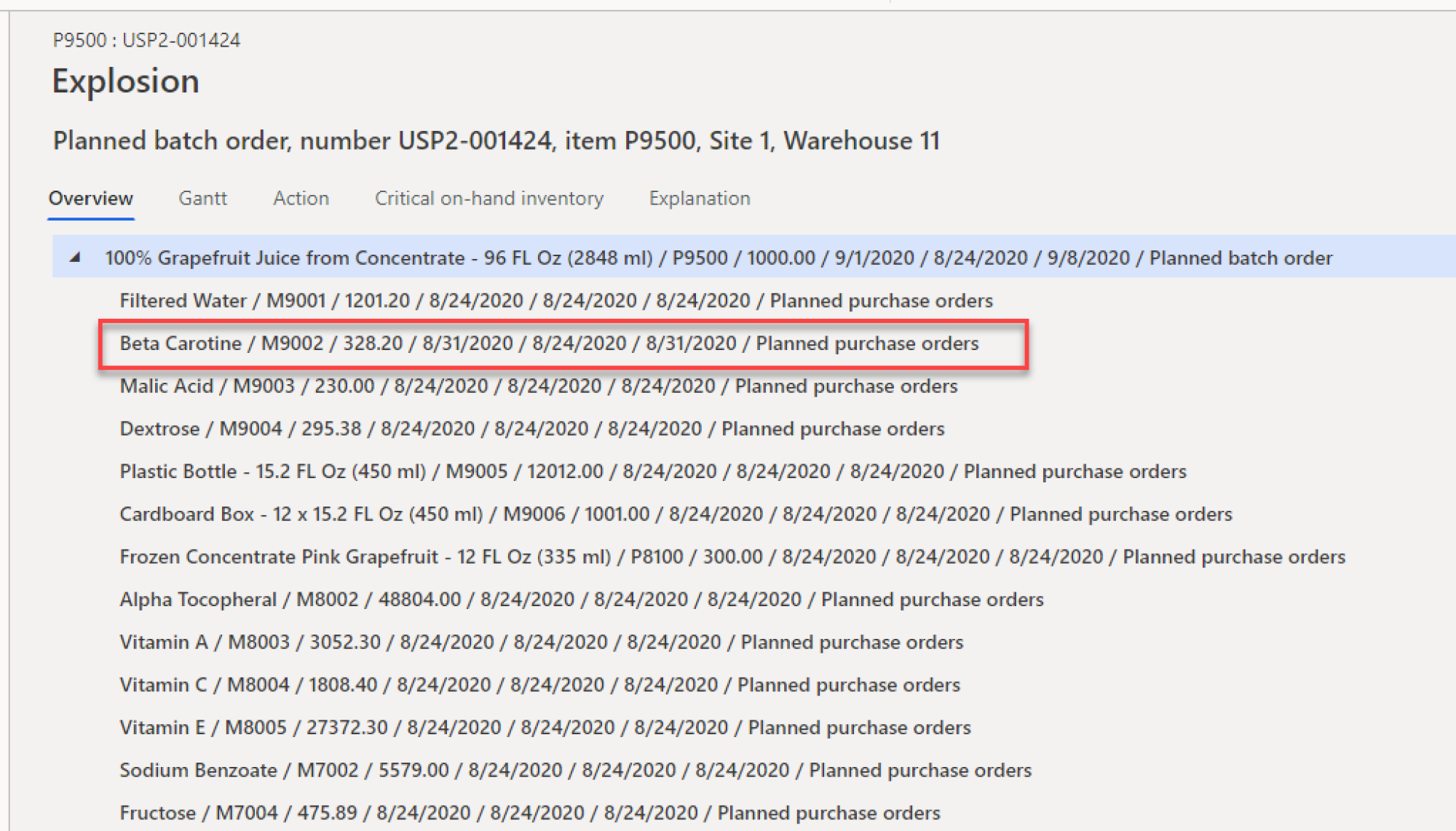

Case III: Lets uncheck the ‘Add calculate delays to requirement date’ and run the master plan again.

- The requested date on the planned order is still 8/27/2020

- The Requirement date on the Planned order is 9/1/2020

- The system ignores the delays in procurement of the raw material and considers that the order can be started on the next working day.

- The Beta carotene is delayed but the system does not account for the delay as the ‘Add calculate delays to requirement date’ is not checked.

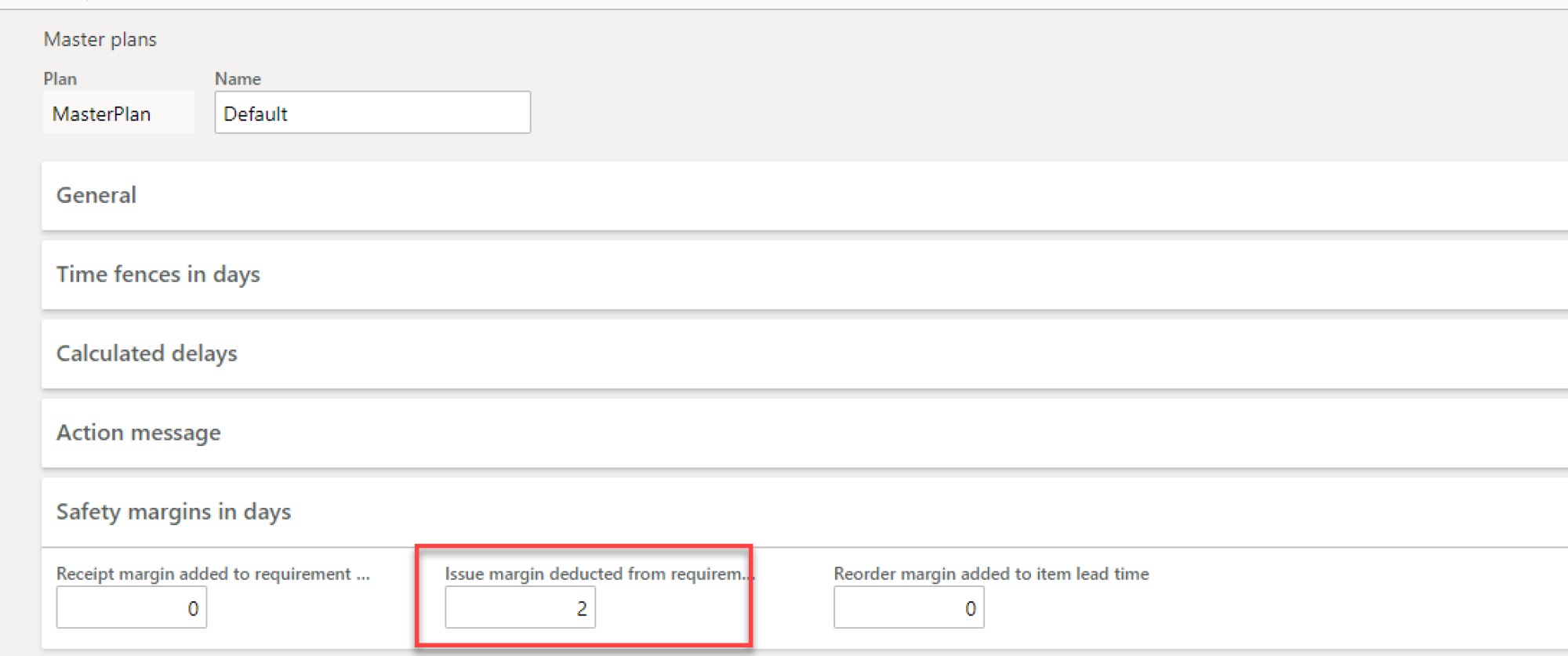

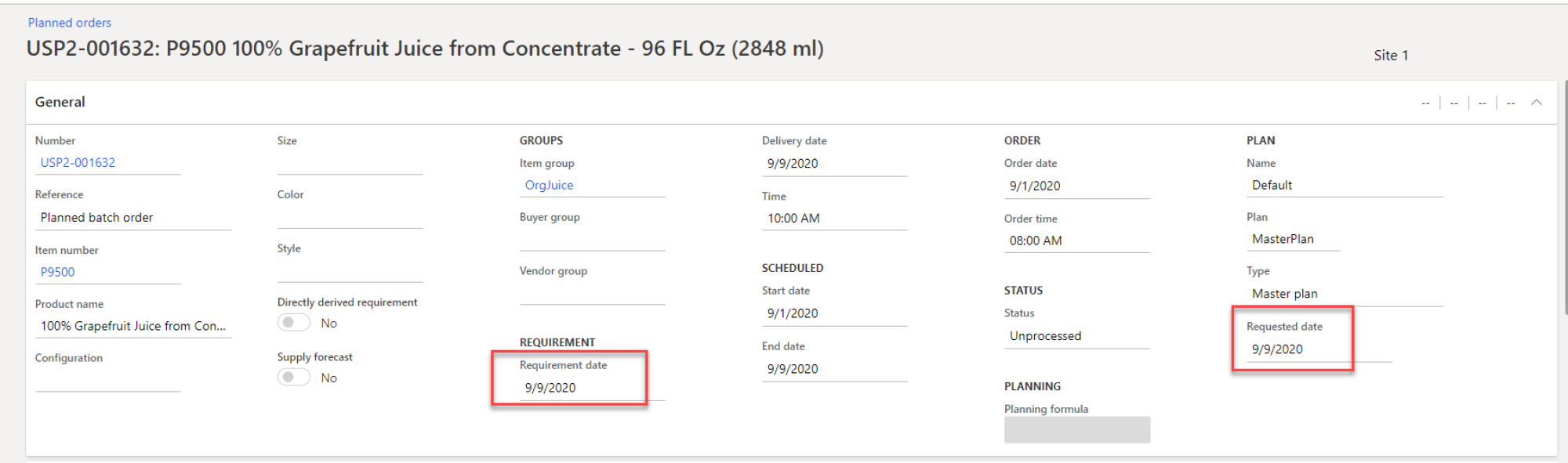

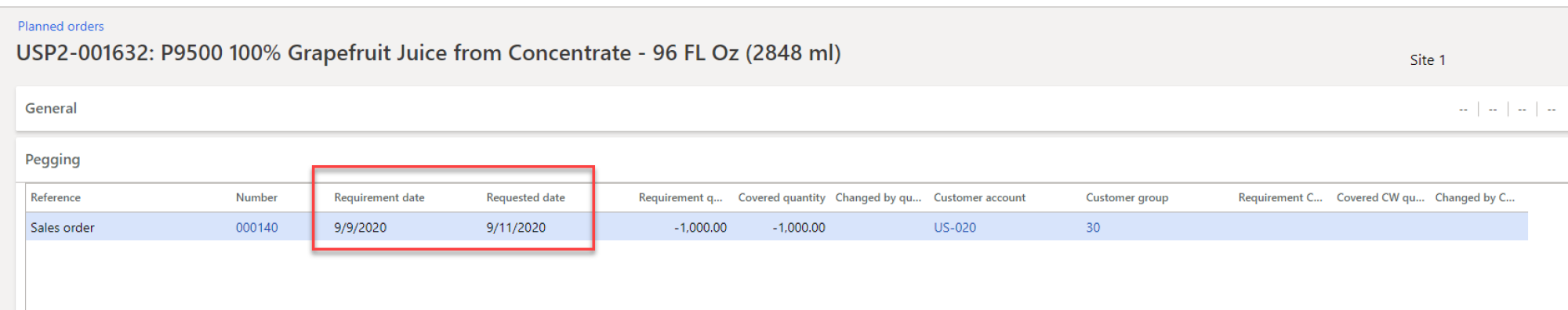

Case IV: Requested date on the Pegging

The Sales order is set with a Requested ship date of 9/15/2020

- Set the Issue Margin on the coverage group or the Master plant to 2 days

- Run the master planning again

The requirement date and the requested date on the planned order are set to 9/9/2020 (9/11/2020-2 days)

- On the Pegging the Requirement date =09/09/2020 and the Requested date =09/11/2020. So the requested date represents the shipment date whereas the requirement date takes the margin into account.

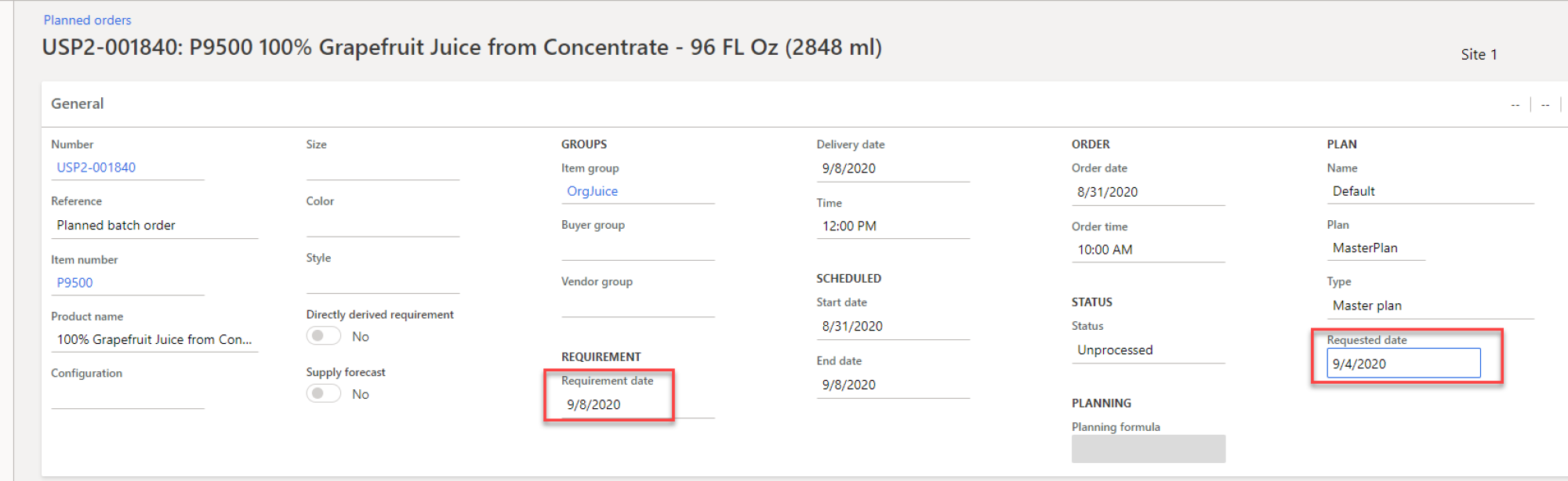

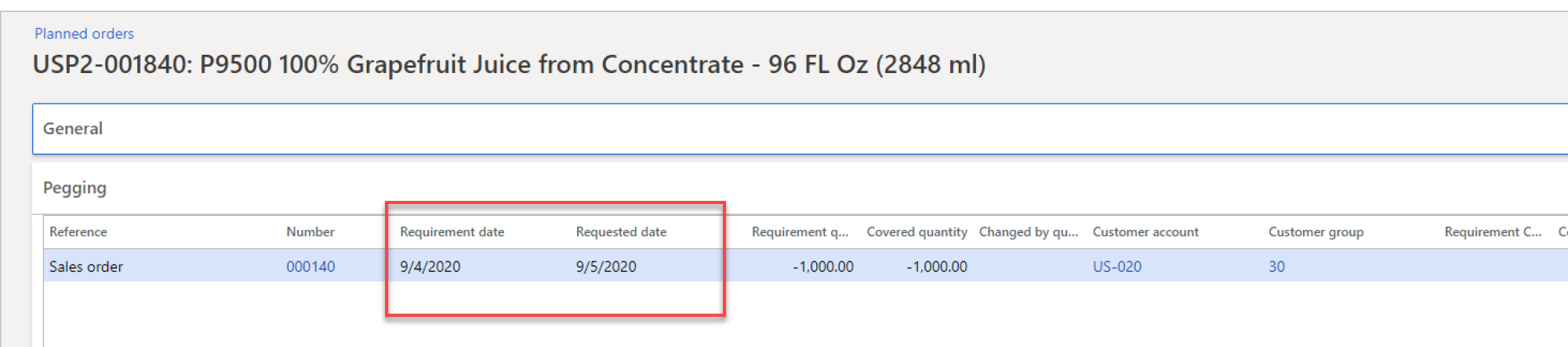

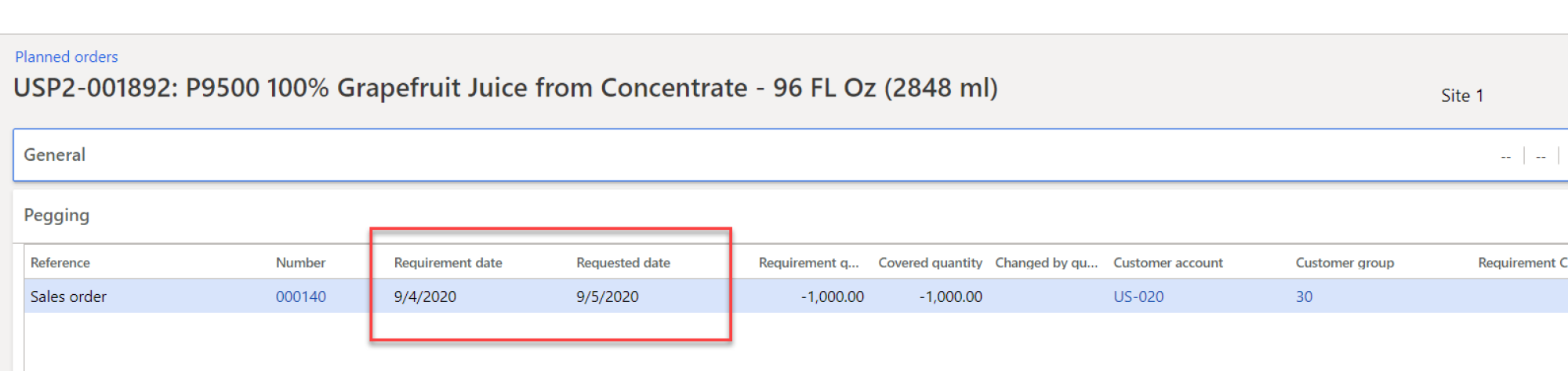

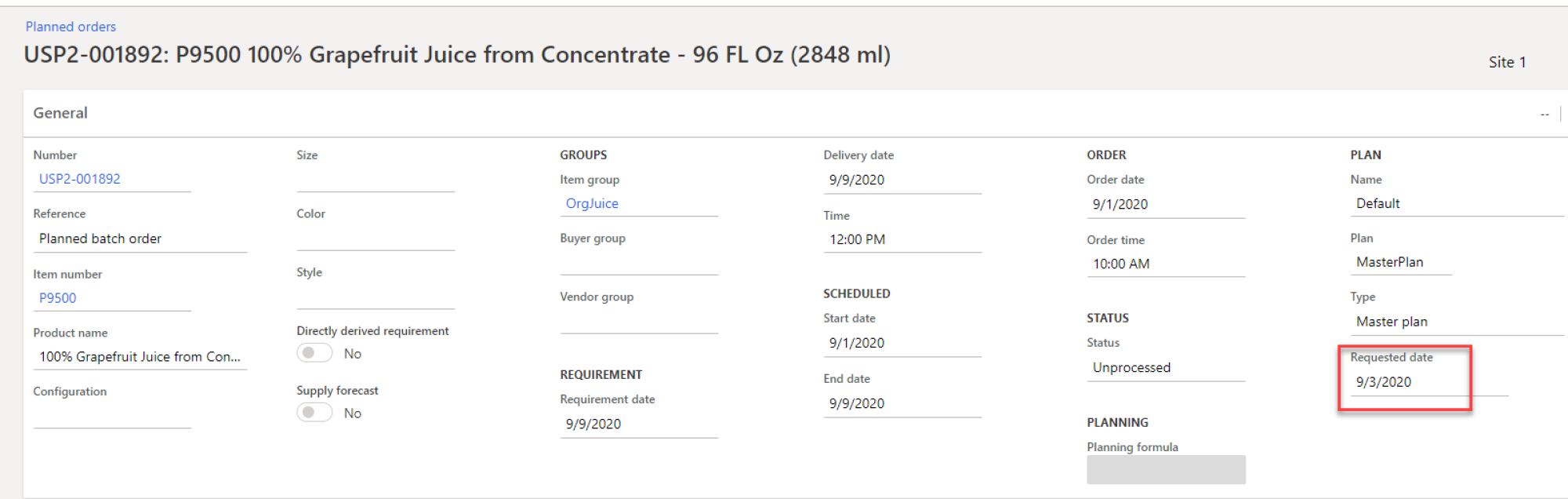

Case V: The Sales order Requested Ship date is set to 09/05/2020 which is a Saturday

Run the master planning again

The Requested date is 09/4/2020 and the Requirement date =09/08/2020 on the Planned order

- The pegging shows the requested date of 09/5/2020 and the requirement date of 09/04/2020.

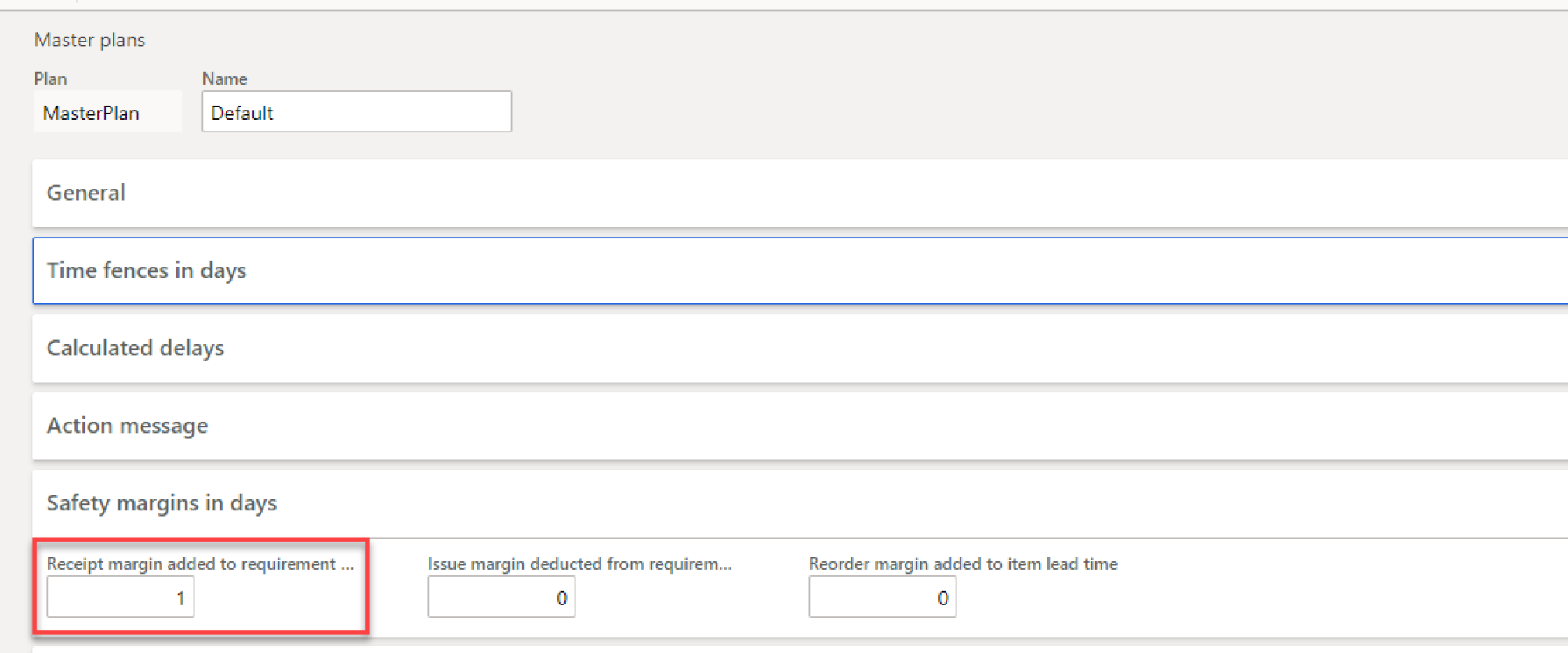

Case VI: Set the Receipt Margin added to requirement date as 1

- The pegging on the planned order shows the Requested day of 09/05/2020 and requirement date is 09/04/2020

The Requested date for the planned order moves to 09/03/2020 as there is a receipt margin of 1 day

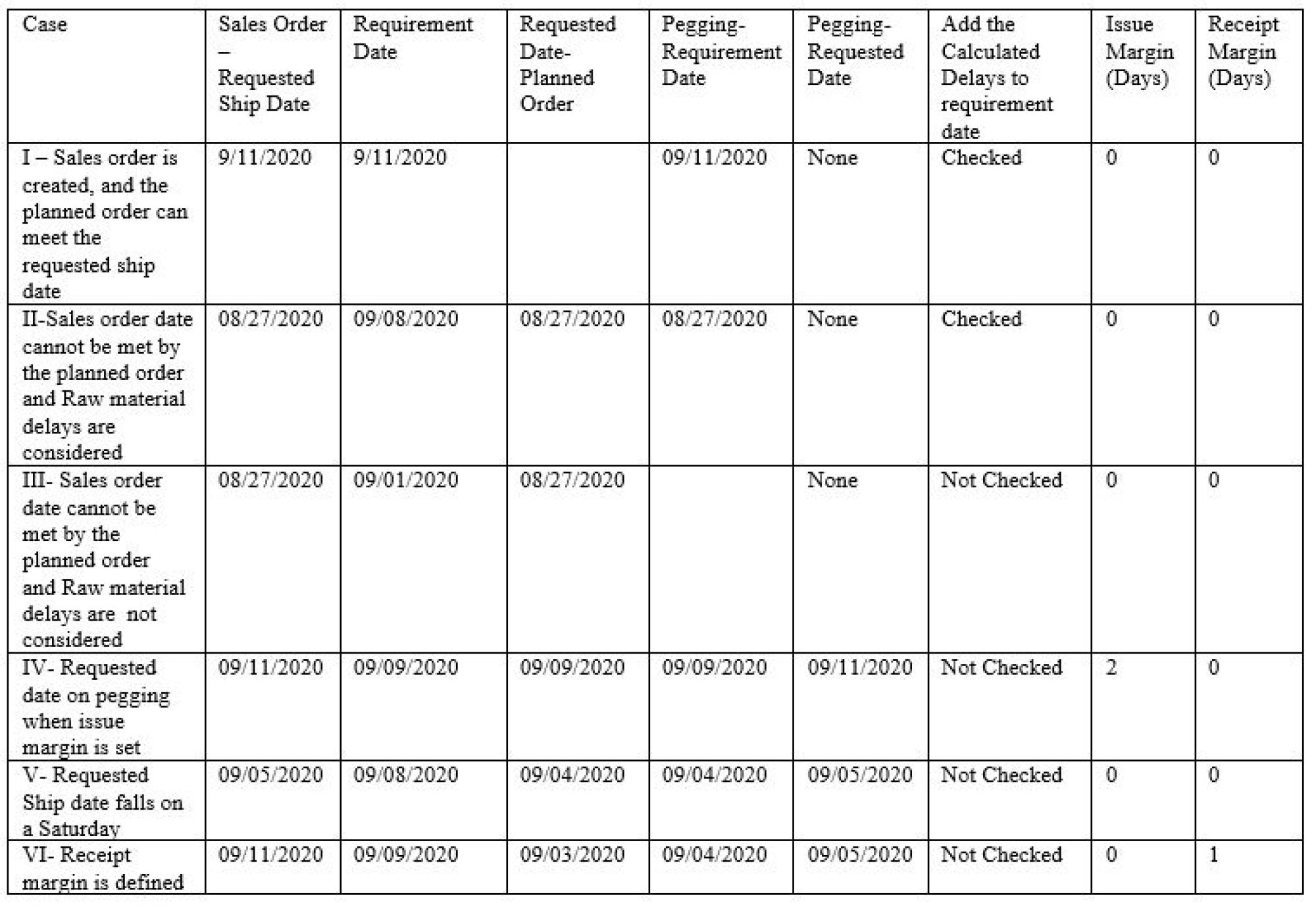

The table below shows the summary of the various cases that have been discussed in this blog